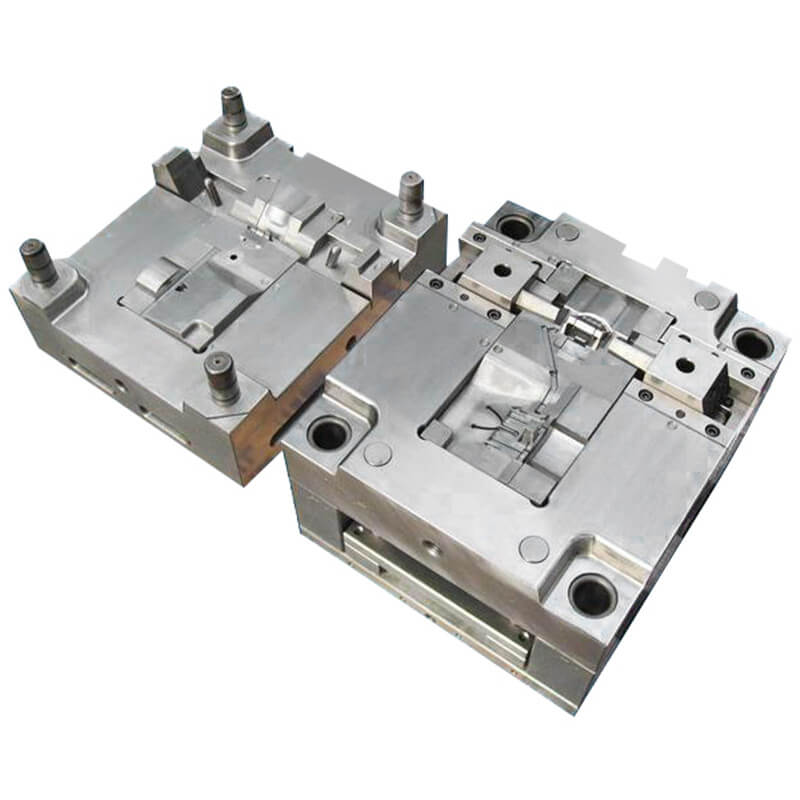

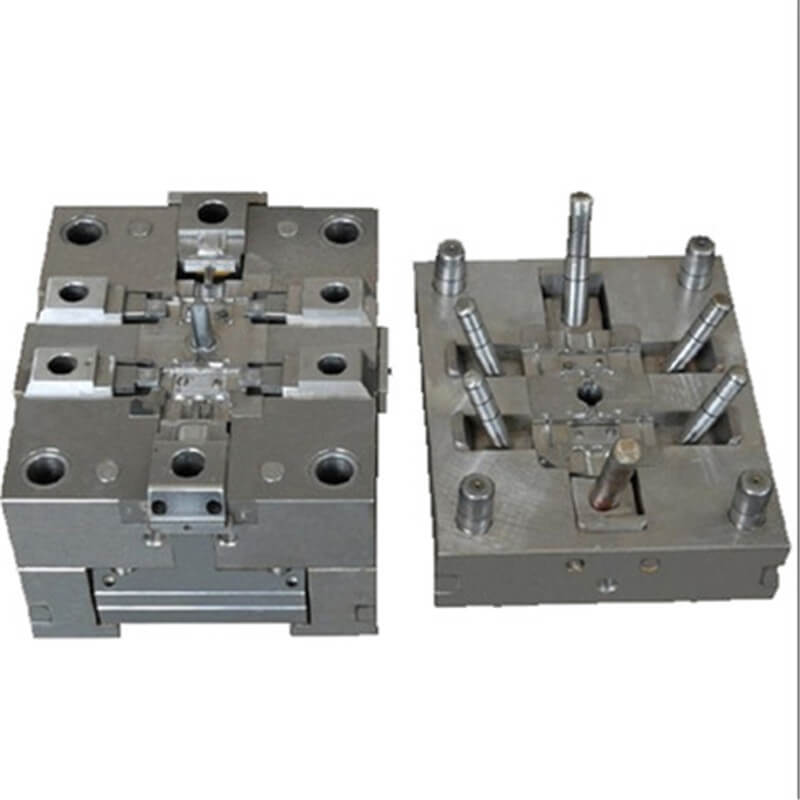

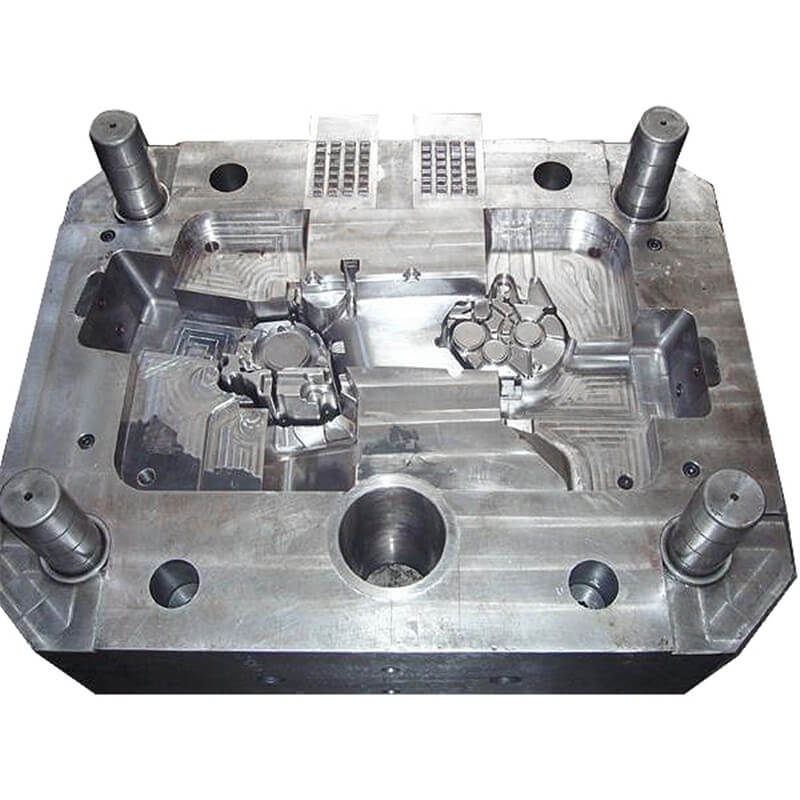

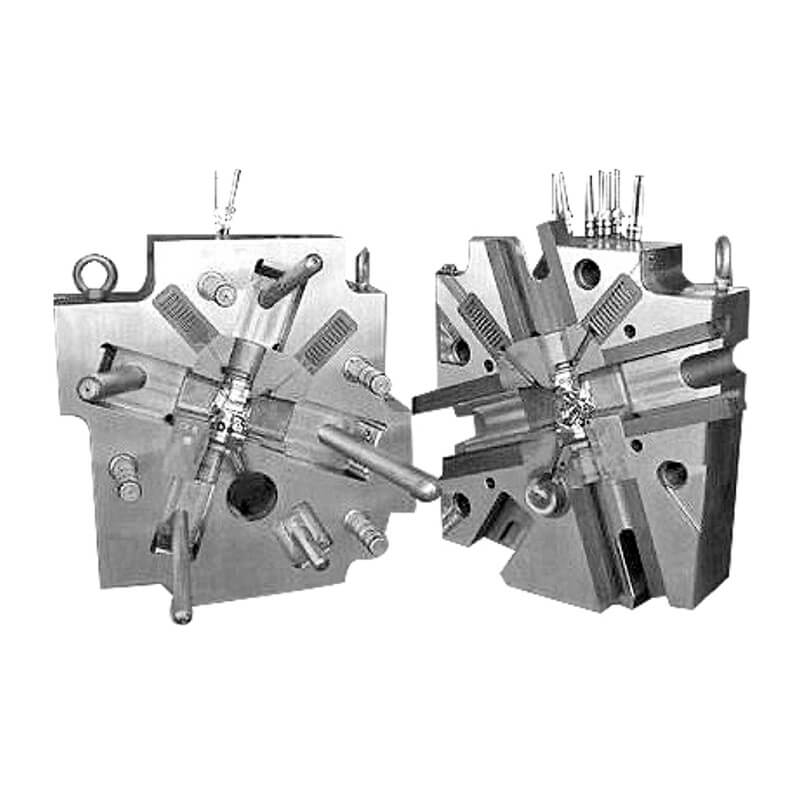

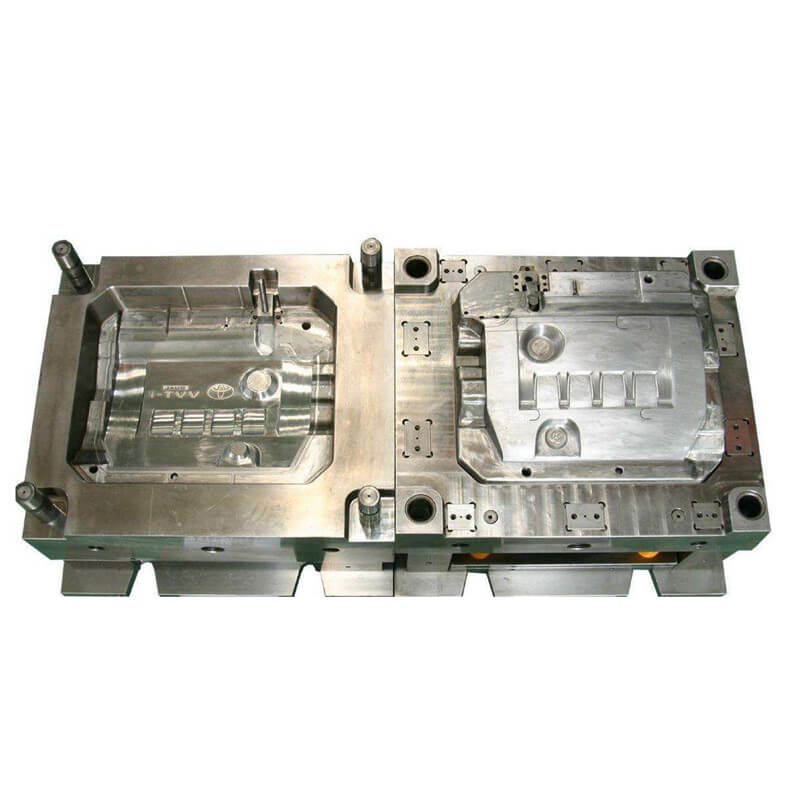

Mold Design and Manufacturing

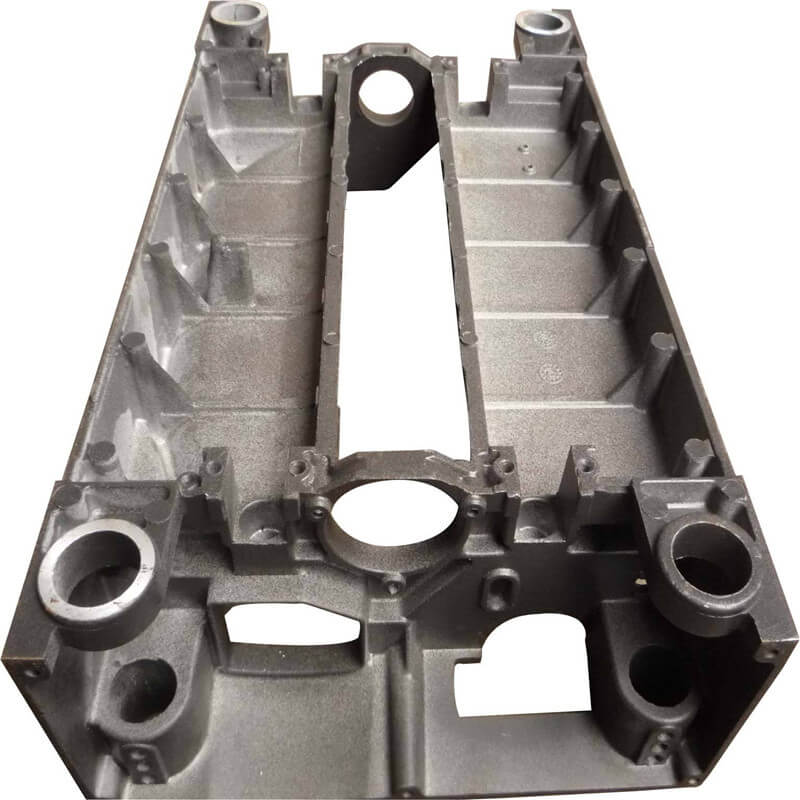

Mof Tech offers die cast tooling and squeeze cast tooling design, engineering, and production tooling with dies up to 750 tons for advanced manufacturing processes for complex, high-performance products. We can also make high quality tooling with long service life based on your drawings, which will help a lot in your own casting production.

Die Cast Tooling Advantages

- Excellent dimensional accuracy (dependent on casting material, but typically 0.1 mm for the first 2.5 cm and 0.02 mm for each additional centimeter).

- Smooth cast surfaces (Ra 1–2.5 micrometres or 0.04–0.10 thou rms).

- Thinner walls can be cast as compared to sand and permanent mould casting (approximately 0.75 mm or 0.030 in).

- Inserts can be cast-in (such as threaded inserts, heating elements, and high strength bearing surfaces).

- Reduces or eliminates secondary machining operations.

- Rapid production rates.

- Casting tensile strength as high as 415 megapascals (60 ksi).

- Casting of low fluidity metals.

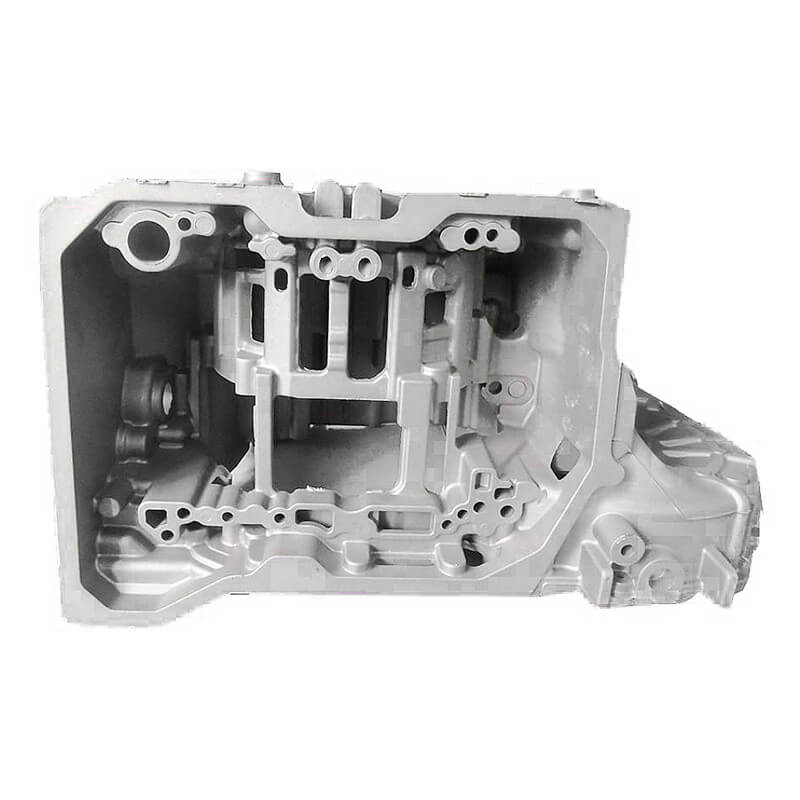

About Die Casting

The die casting process forces molten aluminum, magnesium, and zinc under high pressure and control speed into the cavities of two part tooling molds—a fixer die half and an ejector die half with the impression of the casting component fabricated into the die or mold. Pressure is maintained on the mold until the hot metal solidifies and once hardened, the die is opened to remove the casting.